SBR-VOPROM

up to approx. 10,000 PE tank systems

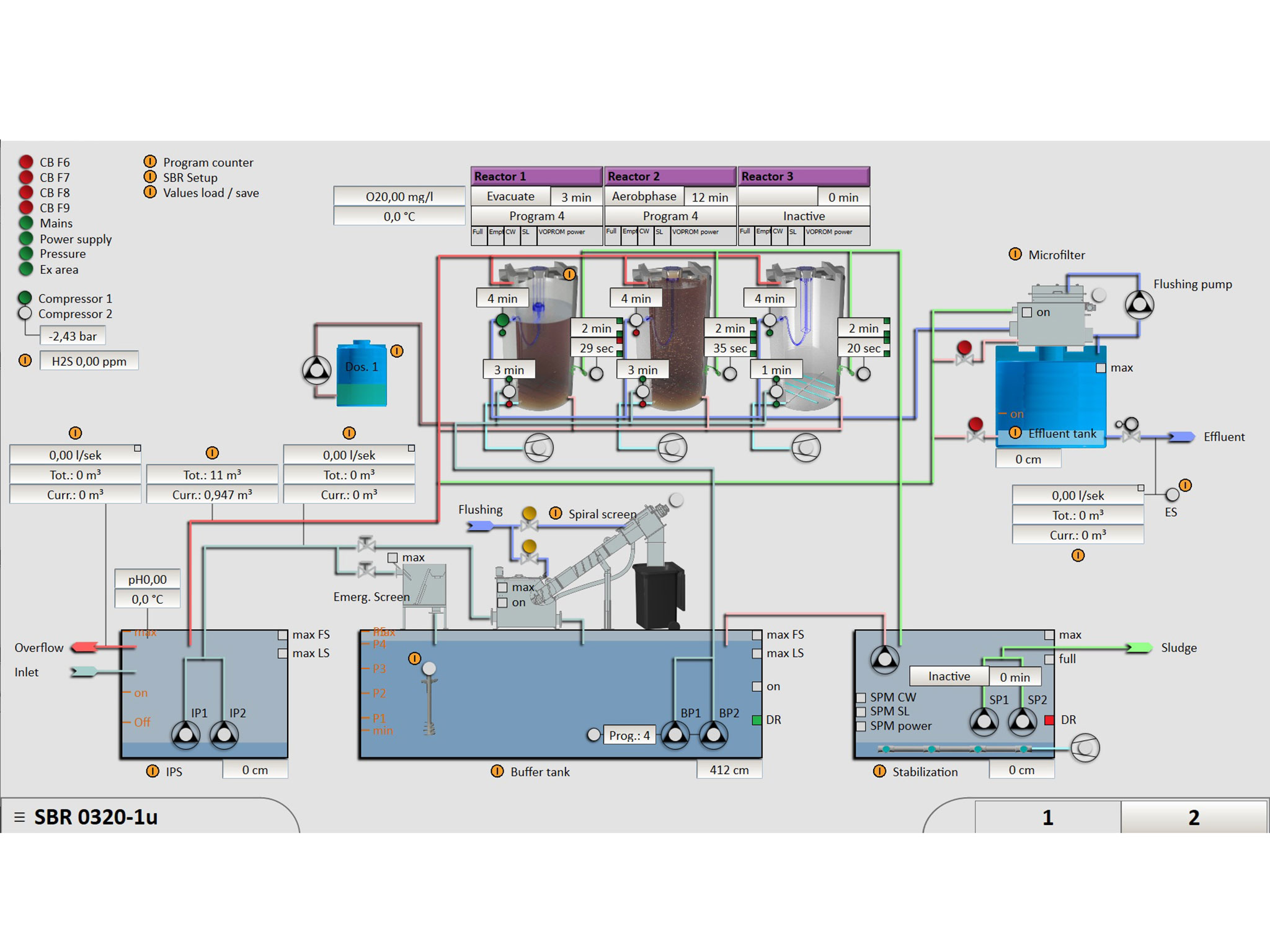

The VOPROM fully biological reactor sewage plant, based on the SBR process, was developed to automate the specified process procedure of the inlet loads.

The reactors are made of polyethylene in a monobloc process. The container philosophy and the specially applied patented technology create a completely new, closed mode of operation process by automatically switching on and off the reactor volumes (redundancy), depending on the inlet conditions. Thus, a high degree of system efficiency is achieved, even with strong fluctuating inlet conditions, and a stable cleaning due to a constant sludge load. In addition, an automatic excess sludge management system is integrated, which eliminates the need for recirculation of excess sludge (unlike conventional continuous flow systems) and guarantees full stabilization.

The PVS-VOPROM system is designed according to the modular principle and can therefore be expanded and/or upgraded even after many years of operation.

In comparison with conventional processes there are the following advantages:

- High and constant plant efficiency despite of fluctuating inlet loads

- Complete housing, no weather-related effects in terms of wear, malfunctions and maintenance work.

- Due to the housing, no possibly negative perception of a sewage plant.

- Small footprint, as well as low operating costs and simple automatic process flow for the operating staff

- low opex

Optional with exhaust air treatment.

Please contact us

for further information